Top Reasons to Use Ultra Violet CIPP

1. Infiltration Installation

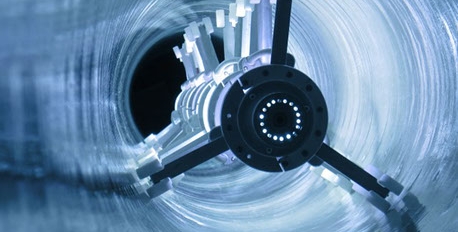

This allows less steps in the rehabilitation process. A sock liner is installed inside of the existing pipe and inflated with compressed air. Then, using robotics, ultra violet light is used to cure and harden the sock liner, thus creating a new pipe. There is no need to pre-line or grout to stop infiltration, due to the liner design.

2. Small construction footprint

The lightweight and portable equipment used during UV curing makes it easy to get into difficult areas — a key advantage for critically tight and sensitive quarters, like near lakes and in backyards.

3. Environmentally friendly and safe

The UV curing process doesn’t use water, so you can leave the heavy water equipment at home. This lessens the footprint and impact on your residents’ properties. Traditional steam and water methods also create gas, causing a need to protect both workers and residents. UV avoids all of that.

4. Faster cure times

You can service approximately five feet of piping per minute although this varies based on liner thickness. This dramatically shortens the time required to rehab piping, which means less downtime in local services for residents.

5. Completely trenchless

All access to the piping when using UV curing is through manholes and via robots. No digging required. Digging can be an expensive and destructive process.

6. Easy inspection

Closed circuit TV is used to inspect the liner for wrinkles or folds prior to curing. Traditional lining with steam or hot water does not enable liner inspection until the pipe is cured out and hardened.

7. No damage to current pipes

There’s no concern about causing damage to your City’s current PVC pipe with the excess heat that’s used in other trenchless methods.

8. Minimal impact to sewer capacity

The stronger but thinner material allows minimal impact on the existing sewer capacity. The high-strength fiberglass properties result in thinner wall design, maximized hydraulic capacity and reduced resin consumption.

9. Health concerns minimized

Odors and effects of the Styrene resin used to cake the pipes is minimized due to encapsulation, which seals and limits harm. There is no potential for the Styrene, which is considered a carcinogen, to migrate into the sewer system.

10. No cooking

This is the beauty and value of UV curing. No cooking allows efficiency and restricts the amount of Styrene released, which promotes an environmentally friendly project.

Bonus reason

It’s cool! UV technology and tools will naturally harden if you leave out in the sun, as it reacts to the UV rays. The uses of UV curing continue to expand. It works on any size pipe and any shape. Some agencies and cities use UV curing to repair highway culverts, watermains and to rehabilitate process piping systems.

Bringing it together

UV curing is the future of trenchless technology due to its efficiency and environmentally friendly techniques and applications, especially if your city is near lakes or water or has a tight, confined area in which to work.