Project Description

The intersection of Routes 9 and 440 with the Garden State Parkway is one of New Jersey’s busiest and most vital cloverleaf complexes. Sinkholes began to appear there after Hurricane Irene in 2011, “Soil was collapsing into large-diameter corrugated metal pipe [CMP] storm sewers and creating big sinkholes,” notes Alkesh liesai, stormwater emergency manager for the New Jersey Department of Transportation (N]DOT). “When we inspected, we found that more than 500 feet of 60-year-old pipe was failing, with joints that were falling apart and some inverts that were completely rotted out. Something had to he done immediately.”Open-cut replacement was ruled out because of the extreme project cost and also the costs of disrupting New Jersey commuter traffic for weeks. The pipe diameters were large-3 00 feet. of 72-indi. bituminous-lined CMP, and about 240 feet of 60-inch. bituminous-lined CMP At large diameters, cured-in-place pipe (CIPP) is relatively expensive, and large-diameter CTPP occasionally slumps or pulls away from substrate during installation.

One stretch of sewer included a 30-degree vertical bend, which could not be negotiated by a prefabricated lining. In addition, because the CMP was in such poor condition, the rehabilitation bad to he structural and had to be applied to the uneven substrate. Finally, weather was a challenge. The repair had to he completed immediately, during heavy storms that. followed Irene, so repairs would have to be made in wet conditions.

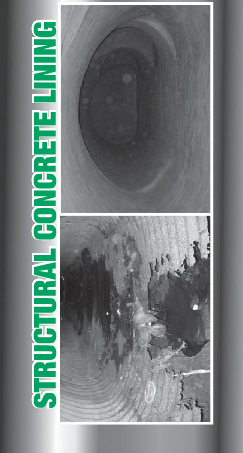

Desai had some familiarity with one viable option: the Centri-Pipe system, a centrifugally cast concrete pipe (CCCP) solution produced by AP/M Permaform. In the Centri- Pipe pmcess, a spincaster is with drawn through large-diameter pipe at precisely calculated speeds. The spincaster sprays on thin layers of cementitious grout; successive layers bond to each other until the desired pipe thickness is reached.

AP/M Pel% maform designers calculate thickness based on depth of cover, soil types, pipe condition, and groundwater pressures, as well as the pipe’s size, shape, and other factors. The result- ing smooth, joint-free concrete pipe lining reinforces and seals the dam- aged host pipe and is designed for full structural support. The material’s high strength-to-thickness ratio maxi- mizes the pipe interior diameter and flow capacity .

“We had to divert now in order to work in reasonably dry pipe,” explains Scott Benner, partner and project manager at Centrifugal Lin- ing Inc., which had the application contract. “But conditions being what they were, we also had to watch the weather and pull the plugs as needed to avoid major flooding.” Once flow was diverted, Benner’s crews used several passes through each sewer, applying thin layers of PL-S,OOO with each pass until a total thickness of 2 inches was reached.

The ability of the to cure quickly was critical for success in the stormy weather, as shown by one amazing event. “We had a storm rapidly develop soon after a Centri- Pipe pæss was completed, one that ultimately dumped five inches of rain in a few hours,” says Benner. “But the next day, there was no damage at all—in just a couple of hours, the Pl.-8,000 had set up quickly enough to withstand being banged around by a big plug and a heavy surge of stormwater. ”

“The project was completed on time and the initial results look good,” says Desai. “So at this point we’re happy with the results, and if it proves to be durable it will also be cost-effective. We will certainly be using this technology again and espe- cially in emergency situations like this one.

” Pipe Jacking Minimizes Utah Traffic Problems As with most highway construction projects, major improvements to 1-15

a high-strength cementi- tious grout made by AP/M Per- maform, to repair sewer joints and in Utah are affecting stormwater drain- age. The project, expected to be com• pleted in 2013, will add two lanes in

“More than 500 feet of 60-year-old pipe was failing, with joints that were falling apart and some inverts that were completely rotted out. Something had to be done immediately. ”

stabilize collapsing pipe sections. P L-12,000, a self-consolidating tar also from AP/M Permaform, was then used to repair the inverts and provide a smooth bottom surface for efficient operation of the spincaster. Then, after the Centri-Pipe spin washer was used for high-pressure washing, pipe casting began.

Working from median staging areas near stormwater inlets to avoid traffic disruptions, Benner made both directions along a 21 -mile corri- dor south of Salt Lake City, extend the express lanes in both directions on the south end of the project, rebuild and reconfigure 10 freeway interchanges and mplace 63 aging bridges, and use 40-year concrete pavement along the entire corridor. Minger Construction of Chanhasen, MN, was selected for the drainage por- [ion of the project to jack concrete pipe under 1-15 to avoid open-cut construc-